As Scandinavia, and especially Sweden is becoming a world-class whisky producing region – not only thanks to big players like Mackmyra but also via smaller craft distilleries spreading the territory – there’s a lot to learn – AND TASTE – when it comes to Swedish whisky. If French are said to be the N°1 whisky consumers in the world, Sweden is actually known for being the biggest malt market per capita…

Box Distilleri, which released its first whisky a few years ago, appears to be the nothernmost working distillery in Sweden. Nestled within a unique environment and climatic conditions (very cold winters and very warm summers), its geographical situation enable the distillery to produce a unique nectar developing a wealth of flavours due to these storage conditions.

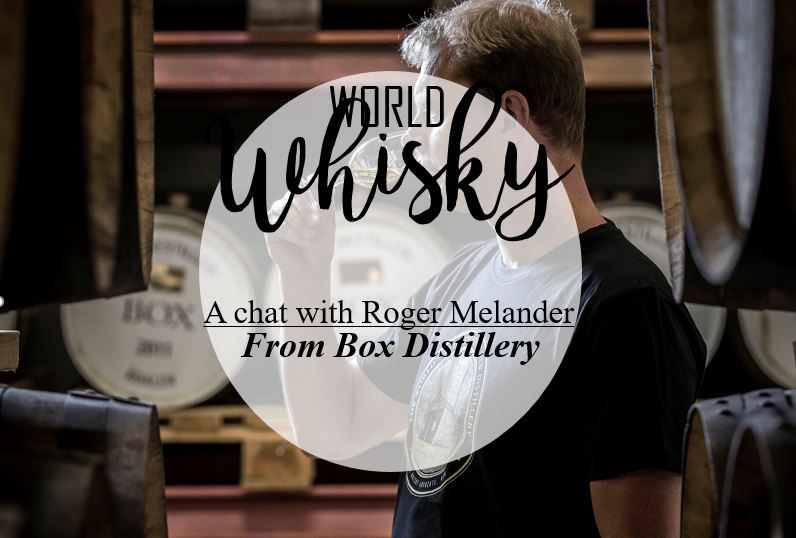

As I wanted to find out more about Box’s current and future projects, I reach out to distillery manager Roger Melander who kindly agreed to answer my 7 questions!

Could you please tell me a bit more about yourself: where do you come from, career background etc. and how did you end up being involved in the Box Distillery project?

.

I’m 49 year old. Born in northern Sweden but grew up in the south. Started my career as a mechanical engineer and worked the last 9 years in my own consulting company.

The interest in producing alcohol started early and I was experimenting with various beverages. My first passion was with beer and I travelled around doing beer tastings. In the mid-nineties the interest in whisky and especially production had grown enormous.

I had some practice at Bruichladdich, Springbank and Benromach and finally I planned to move to Scotland and work with whisky. In the autumn 2010 The CEO at Box asked me if I wanted to be distillery manager at a brand new distillery. An offer that I couldn’t refuse.

So instead of working in Scotland I ended up back in northern Sweden. The hardest part was to leave my two boys back home.

What is your personal relationship with whisky: first sipped, any noticeable milestone in your malted journey, favourite brands/distilleries/flavour profiles/production countries?

.

I started drinking blended whisky and found some malt whisky that I liked, but it was actually when I first got a bottle of Lagavulin that I was going totally bananas. After a few years with heavily peated malt I started to appreciate the elegance in high quality unpeated whisky. Today I can enjoy whisky from all over the world but I’m quite choosy about what I buy to my collection.

Brora from early seventies, older Springbank and Ardbeg just to mention a few favourites. I also have a passion about Japanese whisky and their perfection in production.

What is the overall idea behind the creation of Box Distillery? Could you please tell us a bit more about the spirits you already produce or wish to produce in the future (production capacity, equipment, raw ingredients, casks experimentations etc… Yeap, I’m curious and I want to know everything ? )? What – in your opinion – makes the spirits produced at Box unique?

.

I guess that the overall idea behind Box and many other craft producers is to make money of something you love doing. For me it is still a challenge to see how far we can go in perfection. I have no idea what I’ll do if or when we get there. We are producing two basic recipes, unpeated and heavily peated newmake. For the first 3 years we did equally amount of both, but nowadays about 80% is unpeated.

.

The unpeated recipe is inspired from Japanese flavours with a clean, fruity and malty character. The peated recipe is more like Islay and the west coast of Scotland. Most of the spirit is filled into 1st fill bourbon barrels, but we have some sherry casks and virgin oak from (Swedish, American, Hungarian, French and Asian oak). We have experimented a lot with different toasting levels and combination of toast and charring of oak.

We have since 2011 sold nearly 4000 private casks, mostly 40-litre but also bigger casks up to hogsheads.

Mashing: Semi-lauter mashtun, 1.25 tonnes mash. 5 batches per week.

Fermentation: 3 stainless steel washbacks. Charge 6300 litres. 80 hour fermentation.

Distillation: Two Forsyth pot stills. Charge 3150 litres wash and 1600 litres low wines.

Distillery capacity: Approx. 127 000 LPA. Annually production 102 000 LPA.

I’m sure that the northern climate has a significant impact on our whisky. The cooling water comes from the nearby river with 485 000 litres of ice cold water passing every second.

The temperature variations in our warehouses is huge. From +28°C in the summer to -26°C in the winter that give us a remarkable result in maturation.

Our process water comes from a lake nearby and is incredibly clean and tasty.

We do not use anti foam or any other additives. We will never chill filter or add caramel to the whisky and every bottle will be at 46% ABV or higher.

Do you think Nordic whisky has now become a category on its own? What do you think would best describle it?

I wouldn’t say that there is a Nordic style of whisky. What we have in common is that we are all relative small producers that makes whisky with passion.

Not a week passes without a new distillery project being announced or a crowdfunding campaign launched: how do you think Box is standing out within this highly-competitive environment?

.

I do not see competitors, but colleges in craft. I believe that Box will be a well-known brand in a few years. I’m making whisky that I like and I hope that people will appreciate our bottlings.

Craft distilling has become incredibly huge – as there’s still no official definition, how would you define “craft” and do you think Box will fit into this category?

.

We have, together with Pär Caldenby from Smögen, developed a Craft Whisky Code that tighten up current definitions about whisky. We hope that this will be something that other producers will adopt.

How do you see the future for Box: how do you picture the distillery in 5/10 years time? Any crazy dream you’d like to achieve?

.

Things have gone very fast and we have accomplished a lot over these six years. I’m very proud of what we have done but it has been a lot of work. Hopefully things will be easier in the future and I’m dying to sample a 15 year old Box from a bourbon barrel.

One advantage of having this job is that there is no limit of what you can do. We introduced an educational package called Advanced Master Class. The first one was about toasting levels of oak and the second one was about the physics a chemistry about distilling. There are many more versions waiting in our warehouses.

Another thing that was fun is the Box Whisky Academy. Since 2011 about 160 student has spent a week at the distillery learning more than they need about making whisky.