Today, as part of my partnership with The Craft Whisky Club, and to celebrate #NationalScotchDay, I chose to find out more about one the newest member of the Scotch whisky landscape : Wolfburn Distillery, distilling their magic up North in Thurso!

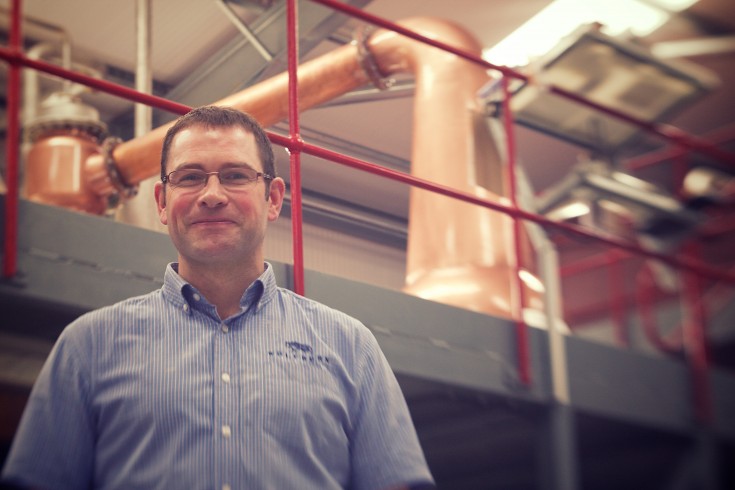

Shane F., Wolfburn’s talented Master Distiller, kindly agreed to answer my 7 questions

First of all, could you please tell us a bit more about yourself: where do you come from – career background etc. And how did you end up setting up the Wolfburn Distillery in Thurso?

I grew up close to Royal Lochnagar – I think the proximity to the distillery had a lot of influence on me from a young age. I was lucky enough to get my first job there aged 16, and that was my entry into the world of single malt scotch whisky. I’ve never looked back! My career took me to several other distilleries across the Highlands and Speyside, and some years ago I became a master distiller. Managing a distillery is of course a big responsibility, but the pinnacle of a career in malt whisky isn’t simply making one, it’s defining an entirely new spirit. That’s the kind of opportunity many people dream of, and they don’t come along very often. That was the single biggest driver for me in getting involved with Wolfburn – that and the excitement of building a new distillery from scratch.

What is your personal relationship with whisky: first sipped – notable milestones on your malted journey – some favourite brands/expressions ?

Perhaps unsurprisingly the first whisky I tried was Royal Lochnagar, with the distillery being so close to where I grew up. I wouldn’t say I fell in love with it instantly – I was very young in any case – but I was certainly in love with the romance and ideas behind good single malt whiskies. I’ve tried many of them over the years. Glenfarclas, where I used to be the manager, is among my favourites. But now my efforts are focused on Wolfburn and trying to create a smooth, pleasant and enjoyable malt. The biggest milestone was the inaugural bottling – the culmination of five years of work, and it got such fantastic reviews. It was just fantastic to see people enjoying it so much.

Could you please tell us a more about the idea behind Wolfburn Distillery and its products: why “Wolfburn”? what makes your spirits unique? What is your current range made of? Raw ingredients – distillery equipment – casks experimentations? We want to know basically everything 😀

The name Wolfburn comes from the old distillery, which was founded in 1821 and which disappeared well over 100 years ago. It’s the name of the water course from where the distillery draws its water. “Burn” is the Scots word for stream, so the name literally means “Wolf Stream”. There used to be wolves in these parts, but like the old distillery they also vanished many years ago!

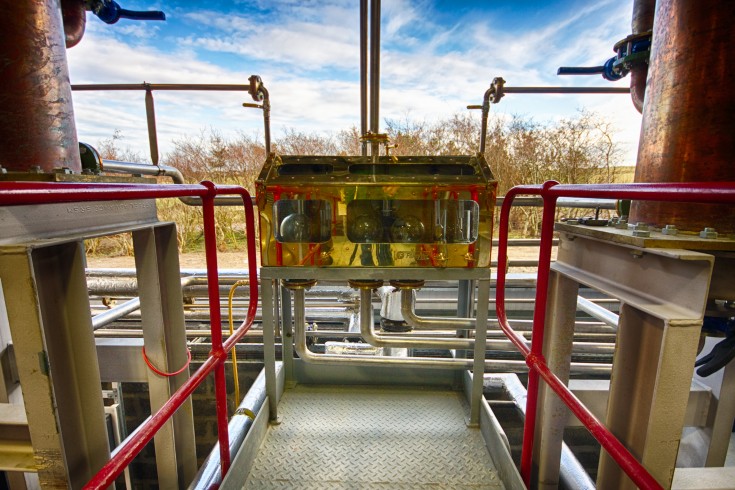

The spirit profile is a factor of many things, but perhaps the biggest are the long time we take over fermentation and distillation. After mashing, most distilleries allow their worts to ferment for around 50 hours. Wolfburn’s fermentation is around 75 hours – 50% longer than the average. At 50 hours there’s no more alcohol to be made, but the yeast is still active, and allowing it to work for longer releases some lovely sweet and floral flavours; you can smell fruits and nutty aromas in the wash. Distillation is similarly unhurried. The longer the distillation, the more contact the spirit has with the copper of the stills, and the more harsh sulphurous compounds are stripped out. Wolfburn’s distillation time is over four hours. The result is a lovely light sweet spirit, with almost zero impurities in it.

As a rule of thumb, if you put good spirit into good casks you won’t go far wrong – and that’s been our philosophy from Day 1. We use a combination of ex-bourbon and sherry casks – they’re hand selected. Maturation is always a work in progress but the results so far have been absolutely superb.

Would you describe Wolfburn as a craft distillery? Why?

To my mind Wolfburn isn’t a craft distillery as such – if only because of the scale; Wolfburn is a good sized distillery. But we do consider ourselves to be craftsmen! We make our whisky the old fashioned way – by hand.

In terms of distribution, how many markets are you currently present on? Are you targeting any specific consumers?

Wolfburn is sold in 21 countries around the world. We’re not targeting any specific group – just people who enjoy fine quality single malt scotch.

What would be a typical day in Shane’s shoes?

That’s a difficult question to answer, as my days tend to vary quite a lot. But I guess a typical day might go something like this: 6am, arrive at the distillery at the same time as one of our apprentices (Charlie or Innes). Get the boiler fired up and the water pumps working. Make a cup of tea and bring all the systems up to temperature and pressure, while milling the first of the day’s malt – roughly 1.1 tonnes. By 7:30 we’ll have started the mash, and the rest of the team will have arrived. The stills are fired up and the first distillation begins around 8am. With the apprentices on hand and everything running nicely I’m free to check emails and undertake maintenance on the large number of machines at the distillery.

Everything needs looking after, from fuel pumps to boiler valves – it pays to check everything as often as possible. We’ll take lunch around 1pm, between the first and second production shifts. By 1:45pm the second mash is underway, and the second distillation. I’ll then pay a visit to the bottling hall to undertake some quality control checks, and to ensure that everything is going smoothly with the day’s bottling. During the afternoon I’ll also check inventories of things such as malt and yeast and order more raw ingredients when required. By 5:30pm the mashing and distillation is finished, and we pump the spirit up into the filling vessel inside Warehouse 1. Then it’s a final check that all systems are powered down, and the distillery is locked up and secure. The day ends around 6pm.

How do you see the future for Wolfburn? How do you picture the distillery in 5/10 years’ time? Any project in the pipeline? A crazy dream you’d like to achieve?

Good question! At the moment everything is running so nicely that I would like to think it will still be very much in the same vein 10 years from now. Realistically we’ll probably expand the operation just a bit – but I never want to reach the scale where automation is required; Wolfburn will always be made the old fashioned way, just like it is today. Obviously there will be more expressions – we have some wonderful sherry casks maturing, for example, so one day in years to come you can expect us to offer a single cask sherry release. But in the bigger picture I love what I do and to be honest as long as the quality stays as high as possible, I’d like to think we can keep it like this for years to come.

PSSST! Find out more about Wolfburn on Craft Whisky Club’s special Highlight Page